2022 Latest Design Bioplastic From Waste - BIO PLA RESIN-REVO DE101 FOR FILM – Chemdo

2022 Latest Design Bioplastic From Waste - BIO PLA RESIN-REVO DE101 FOR FILM – Chemdo Detail:

Product Parameters

Product: Poly Lactic Acid

Chemical Formula: (C4H6O3)x

Cas No: 31852-84-3

Print Date: May 10th, 2020

Description

Poly lactic acid resin, made from corn and other plants rich in starch rather than oil, is a low-carbon functional material with superior processing properties.

Product Packaging & Applications

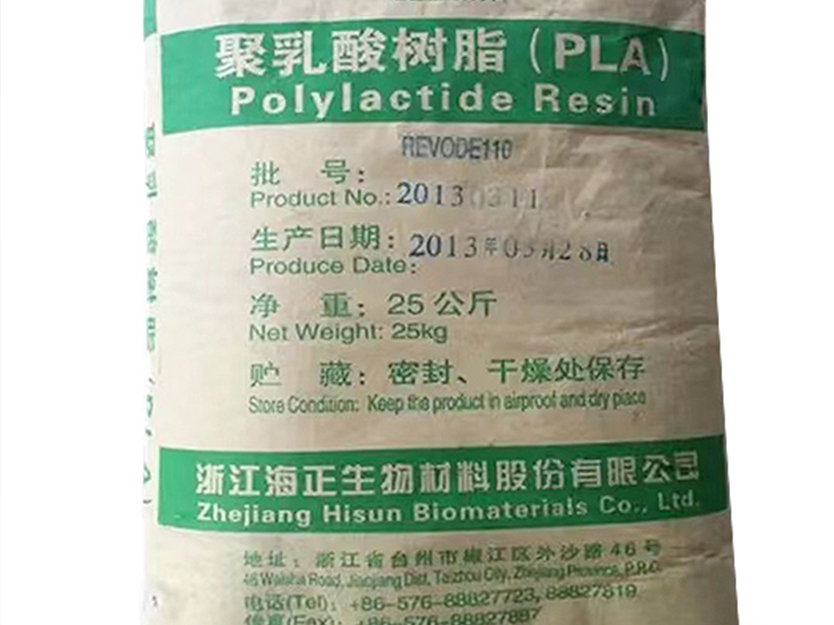

In 25kg kraft bag

Poly lactic acid resin can be used for most synthetic plastics and is suitable for extrusion, injection molding, blow molding, spinning and other molding processes.

|

ITEMS |

UNIT |

METHOD |

REVO |

REVO |

REVO |

REVOD |

|

|

Density |

g/cm³ |

GB/T1033.1-2008 |

1.2-1.3 |

1.2-1.3 |

1.2-1.3 |

1.2-1.3 |

|

|

MVR 190℃,2KG |

g/10 min |

GB/T 3682.1-2018 |

2-10 |

3-12 |

2-12 |

12-40 |

|

|

Melting Points |

℃ |

GB/T19466.3-2004 |

140-155 |

155-170 |

170-180 |

170-180 |

|

|

Glasstransition temperature |

℃ |

GB/T19466.2-2004 |

56-60 |

56-60 |

56-60 |

56-60 |

|

|

Tensile Strengh |

Mpa |

GB/T1040.1-2018 |

≥50 |

≥50 |

≥50 |

≥50 |

|

|

Elongation At Break |

% |

GB/T1040.1-2018 |

≥3.0 |

≥3.0 |

≥3.0 |

≥3.0 |

|

|

Notch impact strength |

KJ/m2 |

GB/T1040.1-2018 |

≥1-3 |

≥2.0 |

≥2.0 |

≥2.0 |

|

Product Details

Polylactic acid (PLA) is a new biodegradable material, which is made of starch raw materials proposed by renewable plant resources (such as corn). Glucose is obtained from starch raw material through saccharification, and then high-purity lactic acid is produced by fermentation of glucose and certain bacteria, and then polylactic acid with certain molecular weight is synthesized by chemical synthesis method.

It has good biodegradability. After use, it can be completely degraded by microorganisms in nature, and finally produce carbon dioxide and water, which does not pollute the environment, which is very beneficial to environmental protection. It is recognized as an environment-friendly material.

The treatment method of ordinary plastics is still incineration and cremation, resulting in a large number of greenhouse gases discharged into the air, while polylactic acid plastics are buried in the soil for degradation, and the generated carbon dioxide directly enters the soil organic matter or is absorbed by plants, which will not be discharged into the air and will not cause the greenhouse effect.

REVODE101 Can Be Applied To

Film blowing and coating products: Blown film modified blend base material is commonly used in starch modified blown film products, which need to improve transparency and heat sealing performance.

REVODE ® Product

Comply with the chemical substance control regulations of China, the United States, the European Union (REACH), Japan and other countries and regions.

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for 2022 Latest Design Bioplastic From Waste - BIO PLA RESIN-REVO DE101 FOR FILM – Chemdo , The product will supply to all over the world, such as: Lahore, Monaco, Albania, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!